Pascati’s Origin

Our story began in 2014 when the only ‘chocolates’ known to Indians were Dairy Milk, Munch, and Kitkats. This is when Devansh Ashar aka Pascati’s founder dared to launch something super foreign in India- a bean-to-bar chocolate company.

But why the heck?

After completing his degree in Hospitality Management from Cal Poly Pomona, USA, Devansh couldn’t help but return to his roots in India. Initially, he joined his family business but soon found his way into the chocolate world when he saw his nephew bite into a bar of ‘compound chocolate’ and struggle with it.

He then tried it for himself and wondered why it was so damn chewy and didn't melt like a smooth bar of Lindt chocolate would. His research led him to understand the difference between a compound and an actual chocolate bar which persuaded him to launch his bean-to-bar chocolate brand.

In addition to Pascati’s aim of giving Indians a taste of real chocolate, we wanted to do our bit to provide a brighter and safer future for our hardworking cocoa farmers. And, hence at the cost of sounding a little braggy, Pascati became India’s 1st Certified, Organic & Fairtrade chocolate maker.

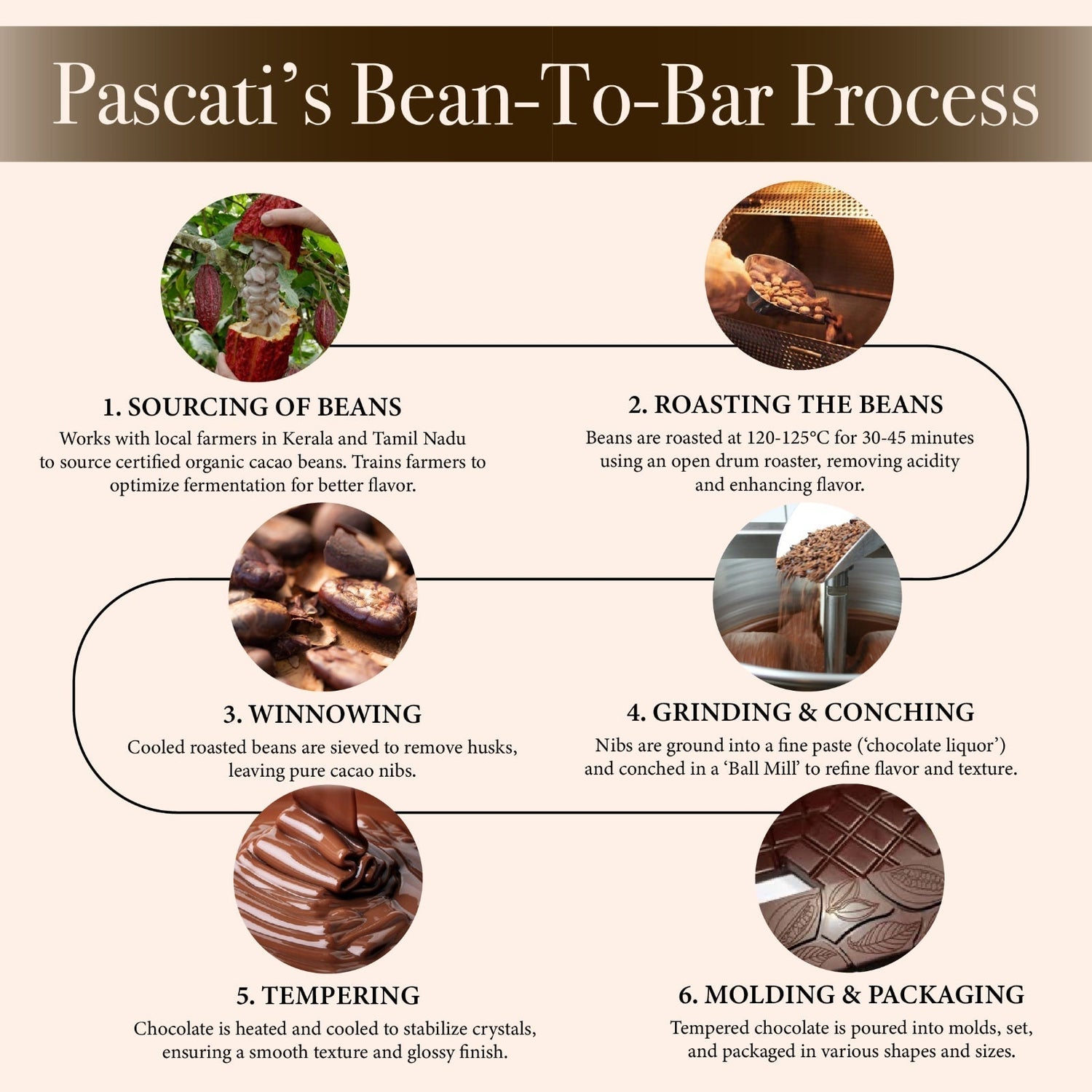

What is Pascati’s Bean-To-Bar Process?

-

Sourcing Beans: Pascati closely works with local cacao farmers based in Kerala and Tamil Nadu to source quality certified organic cacao beans. During our annual visits to these farms, we have been able to foster strong relations with our farmers.

We’ve also made conscious efforts to progressively train farmers to develop fermentation protocols that impact the flavor profile of the cacao which ultimately affects the tasting notes of our final product. In this way, we have ensured that all the important conditions of harvesting, fermentation, and drying are being followed as per our requirements.

-

Roasting of Beans: Once we’ve selected the beans and procured a batch, the beans arrive at our factory where they’re scanned for any defects (if any) before roasting. Here, we run 2-3 small batches of trial roasting, taste-test the beans, and select the batch that matches our expectations.

As Indian cacao tends to be slightly acidic, we ensure most volatiles are removed by roasting the beans at 120°C- 125°C for 30-45 minutes. We do this using an open drum roaster that is also used to roast cashews and coffee in Kerala.

-

Winnowing, Grinding & Conching: Once the roasted beans have cooled down, we pass them through a series of sieves and a blower to remove the husks and other impurities. This process is called winnowing. The winnowed beans are then ground into a fine paste called ‘chocolate liquor’ using a stone grinder. The longer you grind the beans, the smoother the paste becomes.

Next comes the process of conching where we knead and aerate the paste to bring out those complex cacao flavors and tasting notes. For this, we use a machine called ‘Conch’ that we bought from a company in Italy.

-

Tempering: Next comes one of the most complex and intricate processes- tempering. Here, we first melt the chocolate to 45-48°C to obtain the Beta V structure and to ‘kill’ all crystals. The temperature of the chocolate is then brought down to 30-31°C and then up by a degree or two to stabilize it. (Please note that the above mentioned temperature range works only for dark chocolate).

We then perform a ‘temper test’ which ensures our chocolate has been tempered well. If the chocolate sets within 5 minutes at room temperature with a matt finish without any whitish streaks, it means the chocolate is ready for molding. If the temper of the chocolate is not right or if the room is too warm, the chocolate will have a dull finish with white/brown streaks and a crumbly texture.

-

Molding & Packaging: The last 2 steps are pretty straightforward. We then pour the tempered chocolate into molds and allow them to set. Pascati uses a variety of molds to create different shapes and sizes of chocolate bars. Once the chocolate has set, it is removed from the molds and packaged.

That’s it, this is how Pascati brings you its organic and fair trade bean-to-bar chocolate bar. If you ever wish to experience this process in person, we do offer live tours of our factory located in Palghar. You may look to book these tours through our own website here.

Until the next discussion on bean-to-bar chocolate…

Team Pascati